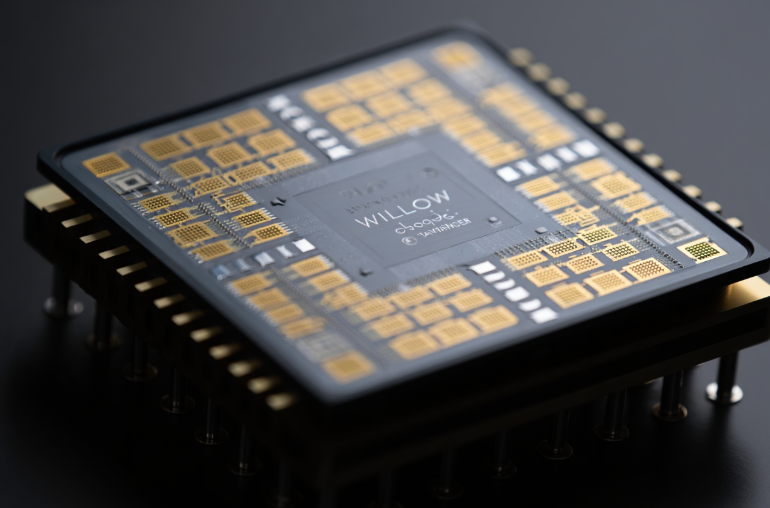

China is rapidly emerging at the forefront of a new wave of industrial transformation through the rise of so-called dark factories—manufacturing sites that operate entirely without human presence. These facilities, often running in total darkness, are powered by artificial intelligence, advanced robotics, and interconnected IoT systems.

Unlike traditional plants, dark factories are designed to function 24 hours a day, seven days a week without breaks, fatigue, or lighting requirements. Every process—from raw material handling and assembly to quality inspection and packaging—is automated and controlled by intelligent systems.The absence of workers on-site reduces safety risks and allows for layouts optimized purely for efficiency.Advocates highlight that these facilities deliver faster output, lower error rates, and reduced operational costs.

By eliminating the need for lighting and heating in certain areas, they also consume less energy, contributing to sustainability goals. From consumer electronics and automotive parts to pharmaceuticals, the range of goods produced in such environments is steadily expanding.China views dark factories not just as a cost-saving measure but as a strategic leap toward next-generation manufacturing dominance.

By merging AI-driven analytics with robotics capable of fine motor precision, these sites can adapt to changing product demands with minimal downtime, creating a model that is both scalable and resilient.Critics warn that widespread adoption may accelerate job displacement, but supporters argue it will also create opportunities in high-skill fields such as AI engineering, robotics maintenance, and digital factory management.For now, one thing is clear: dark factories are reshaping global production standards. What once seemed like science fiction—a facility producing flawlessly in the dark—has become the blueprint for the intelligent, automated, and unstoppable factories of the future.

No Lights, No Workers: Inside the Rise of Autonomous Production Hubs

Saad Wajih

September 15, 2025It’s incredible how fast this is moving, and factories running in total darkness sound futuristic, but the real question is what happens to the people whose jobs are replaced? Progress is exciting, but it needs to be balanced with support for workers.