Scientists 3D-Print Materials That Stop Vibrations Cold

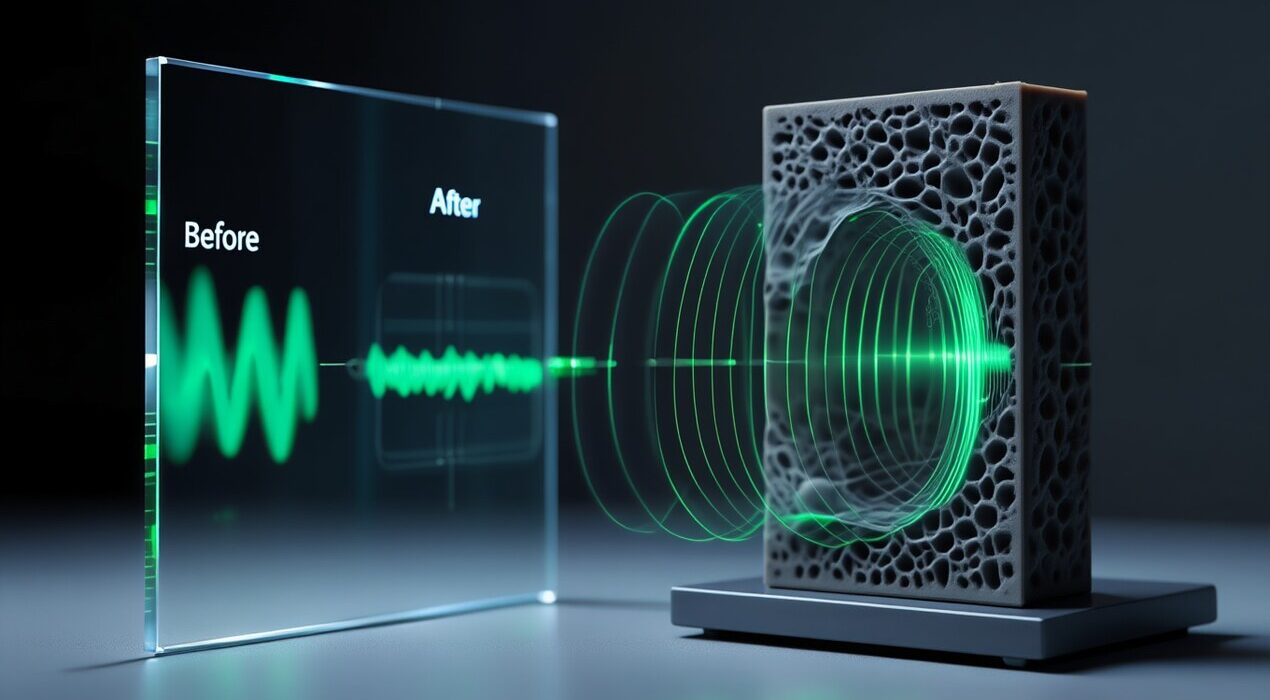

Researchers at the University of Michigan and the Air Force Research Laboratory developed a technique that can stop vibrations cold. They 3D-print a special structure with a complex internal geometry. The design makes materials behave in surprising ways.

How it works

The team created tubular “kagome”-inspired lattice shapes. These shapes redirect vibration energy instead of letting it pass through. They build on the concept of metamaterials, where shape matters more than chemistry. In addition, they used standard 3D printing tools to manufacture the structure. The innovation lies in how geometry alone controls the mechanical behavior.

Why it matters

This ability to stop vibrations cold could change how we build everything from vehicles to buildings. For example, engineers could design lighter parts that still dampen unwanted motion. In the construction world, the method might make skyscrapers or bridges quieter and safer. As a result, machines may run smoother and structures may last longer.

Looking ahead

The researchers note some challenges remain. They must balance weight and strength in these new structures. Also, they need to scale up production for real-world use. However, the early results are promising and show a clear direction for future applications.

In summary, this new 3D-printed material design offers a bold way to stop vibrations cold. It highlights how innovative geometry can drive big advances in engineering.