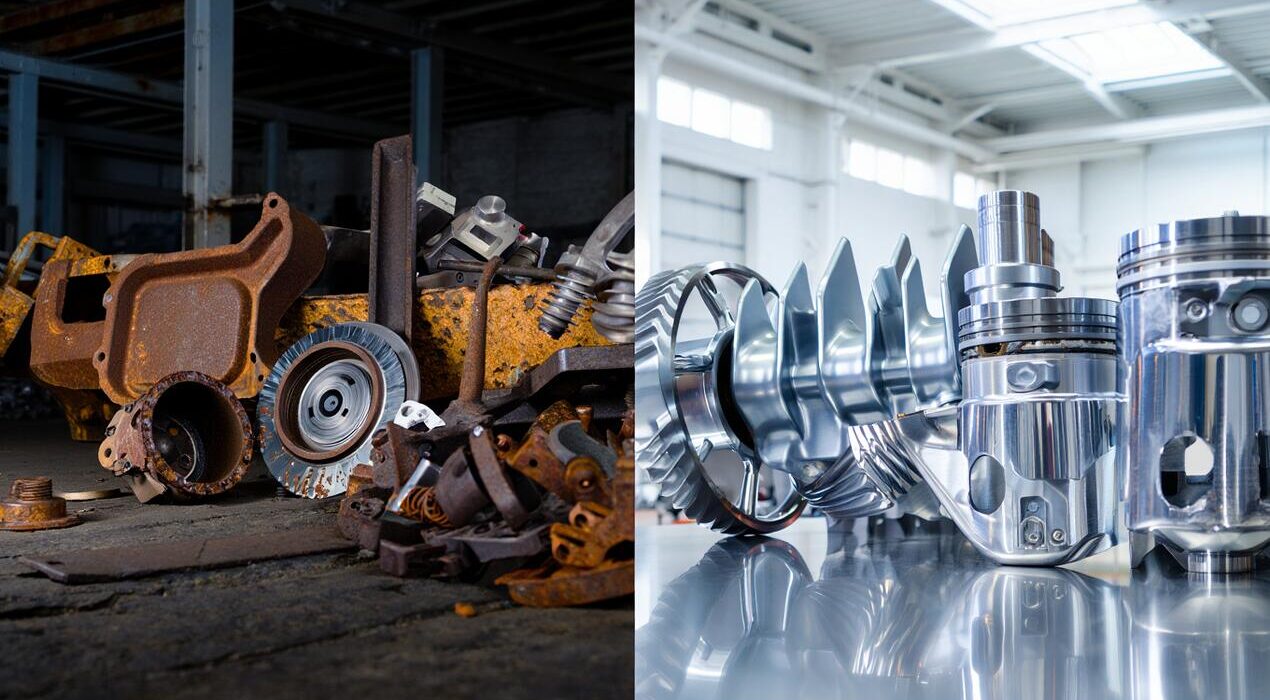

RidgeAlloy Turns Vehicle Scrap Into High-Performance Auto Parts

Scientists at Oak Ridge National Laboratory have developed a new aluminum alloy called RidgeAlloy. The material allows low-quality vehicle scrap to be reused as strong structural parts. This development could improve U.S. manufacturing and recycling.Large amounts of aluminum vehicle scrap are expected in the next decade. Many modern vehicles use aluminum body panels. However, impurities in recycled scrap usually prevent reuse in high-performance parts.

Recycling Aluminum Is Difficult

During shredding, aluminum scrap collects impurities such as iron. These impurities weaken the metal. As a result, manufacturers downgrade scrap or ship it overseas.Primary aluminum remains the main choice for strong auto parts. However, producing it requires high energy use and imported raw materials.

RidgeAlloy Solves the Problem

RidgeAlloy tolerates higher impurity levels. Scientists designed it to maintain strength and durability. Therefore, it performs well even when made from mixed scrap.The research team used advanced computing and lab testing. These tools helped identify the right metal mix faster than traditional methods.

Proven in Real Manufacturing

Manufacturers cast actual auto parts using recycled RidgeAlloy. The parts met industry standards for strength and safety. This confirmed the alloy works outside the laboratory.Using recycled aluminum saves energy. In fact, melting scrap uses up to 95 percent less energy. Therefore, RidgeAlloy supports lower emissions and cleaner production.

Impact on U.S. Supply Chains

The U.S. already has strong scrap recovery systems. RidgeAlloy helps keep recycled aluminum domestic. As a result, it reduces reliance on imported materials.By the early 2030s, RidgeAlloy could support large-scale production. It may serve automotive, industrial, and transportation sectors. This makes recycling more valuable and efficient.